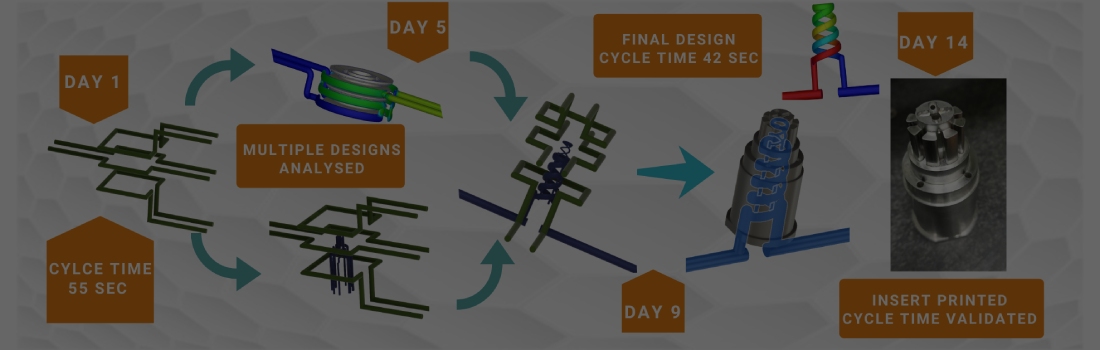

SWIFT INSERTS Development Process

Step 1. Part Identification

Step 2. SWIFT INSERT Design

Step 3. CAE ANALYSIS

Step 4. Production of SWIFT INSERT

Step 1. Part Identification

Consult with MNAM Experts to select part

Lookout for Large Asymetric Parts with huge production volume

Step 2. SWIFT INSERT Design

MNAM pre analyse the parts before designing cooling circuits

MNAM Desgin Engineers design the SWIFT insert

Step 3. CAE ANALYSIS

Engieering analysis with industry Standard software MoldEx 3D

Identify the Warpage Issues, predict the Cycle time criticle for ROI calculations

Step 4. Production of SWIFT INSERT

Additive Manufacturing & post processing of SWIFT INSERT

Mould assembly and validation of SWFIT INSERT

Value additions

- As much as 80% savings in Cycle times for OEM’s

- Lesser Part Warpage and Shrinkage

- Improved Packing Times

- Improved tool life

- Increased Production Capabilities for job shops

- Insert Development time as short as 2 weeks.